We need next generation, reliable and robust communication

Communication is an essential part of a digitalized, intelligent industry. Having real-time information about anything, anywhere available everywhere at all times is an important step for the mines of the future. Ericsson leads the way!

Positioning both increase safety and save a lot of time in the mines of the future

Generic Collection of Positioning gives us safer mines as we know where things are. Mobilaris and IGW join forces to create Low-cost Mass Localisation of Assets will help people both today and tomorrow.

Communication and Positioning

Objectives

This WP demonstrates state-of-the-art communication and positioning technology, for use in a mining environment. A versatile, integrated, and highly adaptable network will support communication needs and a variety of techniques will support positioning needs, for all use cases and applications throughout the demonstration mine. Use cases that the communication and positioning should support include real-time people interactions, safety, collection and transmission of sensor and process data, process control, remote operation of machines/vehicles/robots, monitoring, collecting position/location data, other Internet of Things (IoT) machine-type communication, etc.

Tomas Jönsson

Master Researcher Radio networks, Ericsson

Working together in projects like SIMS, with representatives from all parts of the mining eco-system and from leading

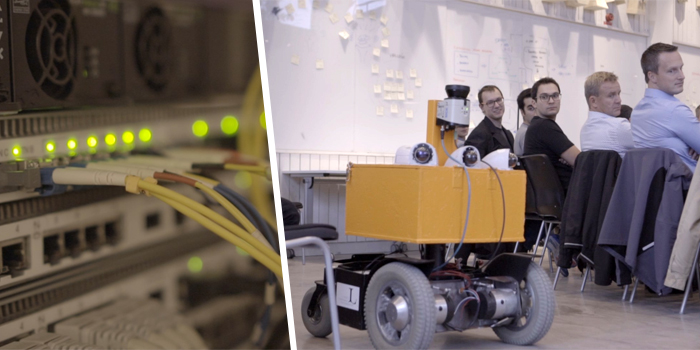

Image to the left: Data Transfer Demonstration using multiple cameras.

First 5G radio network in an operational underground mine

The SIMS project partners Boliden and Ericsson together with Telia have deployed the world’s first 5G network using New Radio (NR) in an operational underground mine – the Boliden Kankberg mine.

Productivity and safety requirements are very high in the mining industry. This customer configured network can function stand-alone, allowing mining operations to continue even if communication is disrupted to the mine.

- “We work actively with robotization to improve productivity and safety in the mine which requires future proof communication solutions. 5G is an important component enabling advanced automation and by that, a safer and more sustainable mine”, says Peter Burman, Program manager at Boliden.

5G technology is superior to other communication solutions for connectivity in demanding environments like mining and manufacturing where continuous operations and close monitoring of processes are required. With characteristics like very low response times and the option for local data handling, 5G is the best suited technology to meet the safety and efficiency requirements of the mine.

- “5G is designed to support industry automation and industrial IoT and will be a platform for innovation in industries”, says Magnus Frodigh, Head of Ericsson Research. “The Boliden underground mine is a great example of a sector with tough requirements that will benefit immediately. 5G will ensure connectivity for applications with high performance requirements.”

- “Industry 4.0 is becoming a reality. This is another good example of how 5G can be used to build networks adapted to the customer’s operations. To guarantee safety in the mine, for example, the network must function even if communications to the outside world is disrupted. Reliable communications can now be secured with the network we have built”, says Magnus Leonhardt, Head of Strategy and innovation at Telia.

The achievement builds on long-term collaboration between ecosystem partners; identifying requirements, including these in standardization and design, and demonstrating technology in a mining environment with key mining use-cases.

A foundation for digitalized, intelligent industry

Communication and positioning are essential parts of a digitalized, intelligent industry. Having real-time information about anything, anywhere available everywhere at all times takes knowledge and control of industry processes to the next level.

For digitalized mining to become reality, we need reliable, robust communication that can support the requirements of the next generation use-cases like connected sensors, remote-controlled machines, and support for a mix of very different service types in one, versatile network.

It’s also an important part of the picture to make information available in ways that are simple and convenient enough to be truly useful.

Part 1

Part 2 – SIMS WP3 World’s first 5G NR in an operational underground mine

Part 3 – Remote-controlled mining machines over 5G enabled industrial communication network

Positioning data increases safety and saves a lot of time in the mines.

It has been great to showcase what can happened when different companies can join forces to meet the demand from the mines of the future. A successful venture showing the result as expected and more. We now have even more ideas on go from here!

Mass Localization. Finding RFID tags matter.

Traffic awerness increase security.

Generic Collection of Positioning Data enables future wonders.

From cold start to navigation makes the system fast to use.

Arne Gylling

Project Manager - IGW

SIMS has been a great commitment for us at IGW. It have been really fun to be able to contribute with technical expertise and infrastructure to make the mines an even safer workplace and to help people to find things in the mine.

Leif Johansson

Mobilaris

This have been an exiting experience, both in terms of developing MMI (Mobilaris Mining Intelligence) and the opportunity to work close to IGW and all the inspiring partners within the SIMS consortium.